December 2021 – Current

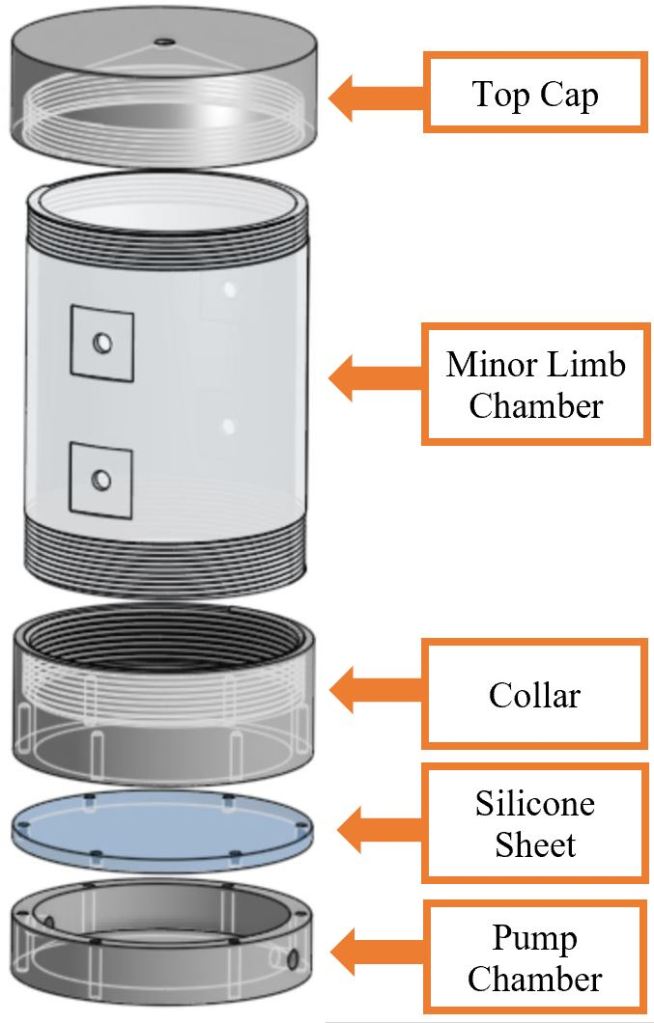

Multi-Extremity Preservation System

Skills/ Programs Used: Arudino, Circuits, Excel, Data collection: LabVIEW, ANSYS, OnShape, Solidworks, Simulation: Solidworks Simulations, ANSYS, Technical Writing

Description: This is my college capstone project, consisting of a team of 4 undergraduate students. The goal of this device is to provide severed ears, noses, and thumbs with sufficient nutrients and oxygen during transport to a hospital for reattachment. My contribution to the project so far is team and project management, and the design of the device. It is being machined this summer to be tested in the fall semester.

January 2021 – Current

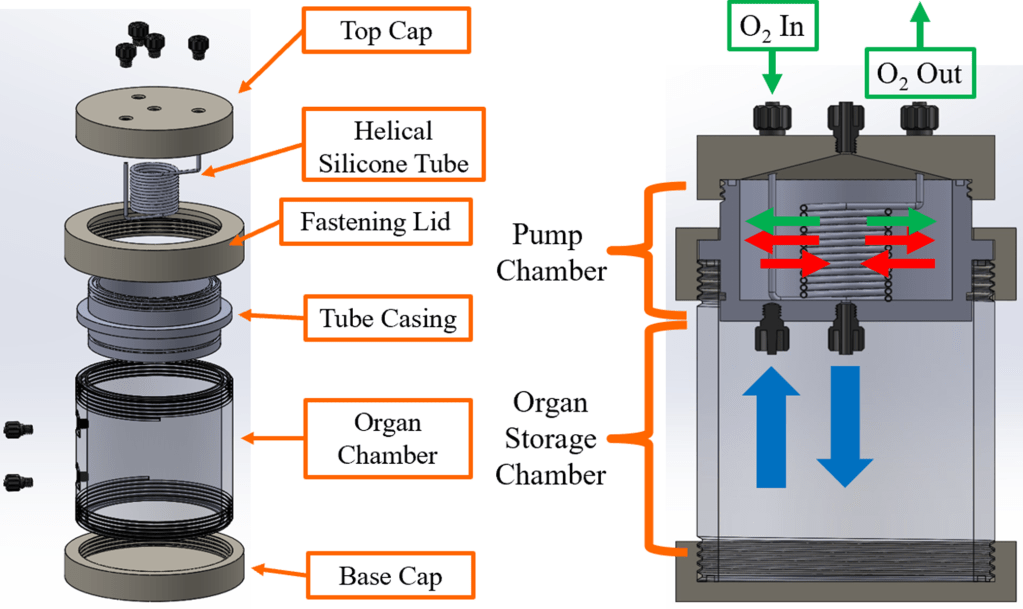

Versatile Organ Preservation System

Skills/ Programs Used: Arudino, Circuits, Excel, Data collection: LabVIEW, ANSYS, OnShape, Solidworks, Simulation: Solidworks Simulations, ANSYS, Technical Writing

Description: I began working in a team of 5 (1 Ph.D. student, 2 graduate students, 2 undergraduate students) to test and engineer a novel organ preservation device (MOPSY). The device works by perfusing the organ with an oxygenated perfusion solution that circulates within the device. My contribution to the design thus far includes helping with the redesign of most of the device pieces (two interpretations) and making the device completely non-electronic through the use of a pneumatic circuit. I collected over 100 hours of data testing the device, to later analyze it.

I am the first author of 6 abstracts, and aided in writing two articles, one published and one in review.

January 2022

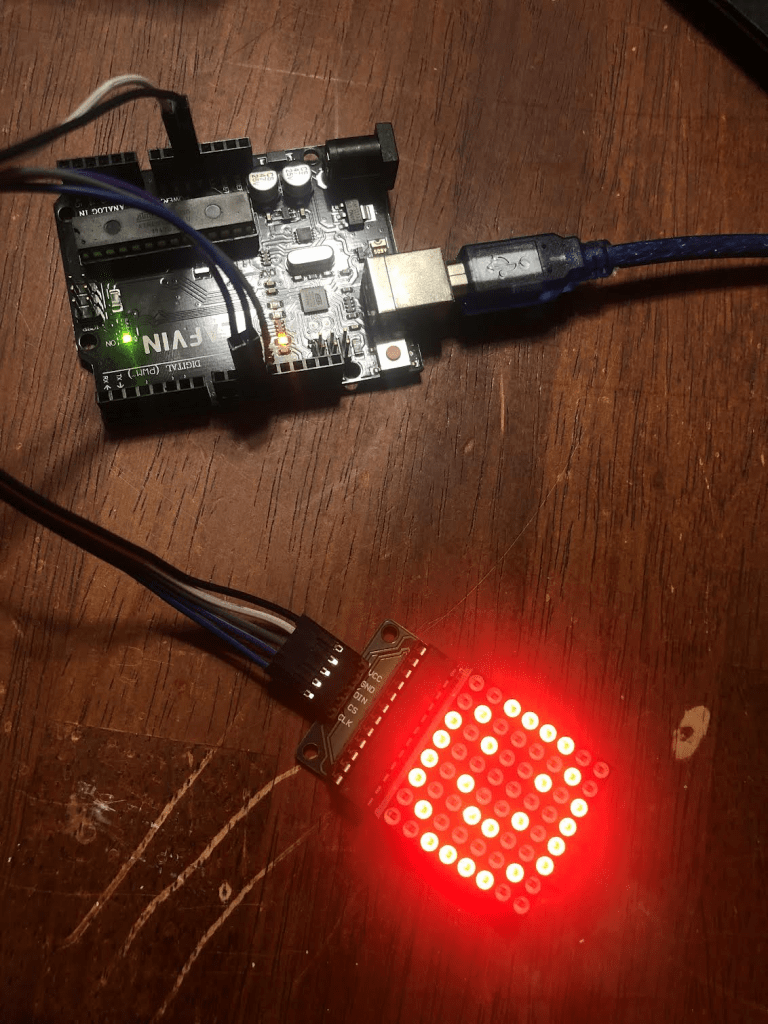

Arduino Project

Skills/ Programs Used: Arudino, Circuits

Description: I altered a basic Arduino code I found online to fit the circuit I designed to make the LEDs flash between a smiley face, a straight face, and a sad face. This was just an easy project I did while I had covid to refamiliarize myself with basic coding and circuits.

October 2021 – December 2021

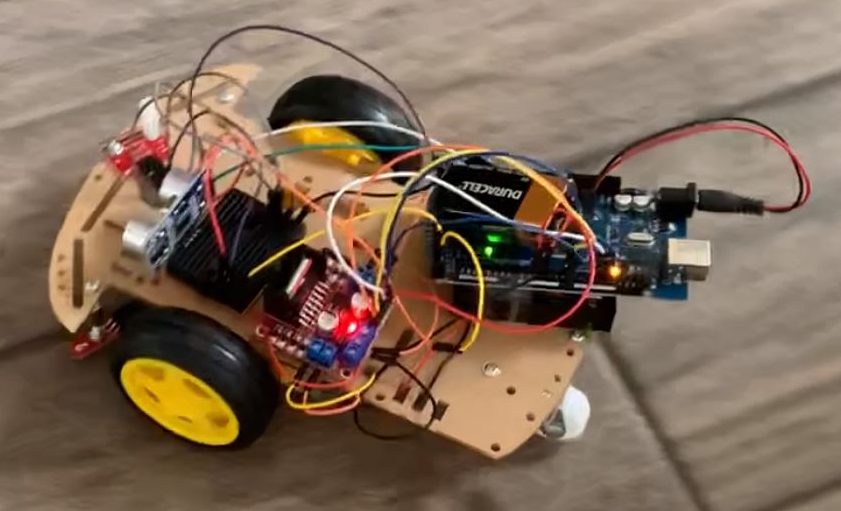

Self-Driving Car

Skills/ Programs Used: Arduino, Circuits

Description: Our team goal (4 students) was to construct a wheeled robot utilizing an array of sensors, motors, and integrated structures, to either disable or through force, push an opposing robot out of a 3-foot diameter arena. I helped with coding and the assembly of the bot.

September 2020 – August 2021

Supraglottic Airway Devices Project

Skills/ Programs Used: Excel, Arduino, Performing Mechanical Tests, Technical Writing, Data Collection

Description: I interned on a team (2 graduate students, 2 undergraduate students) to perform military standard tests on 12 supraglottic airway devices (SGA) to compare and decide on the most effective design. SGA devices are an alternative airway management technique to endotracheal tube intubation (ETI). Reports have shown SGA devices are easier to use and take fewer attempts to provide patent airflow to the patient when compared to ETI. This project was with UTSA’s Medical Design Innovations Lab funded by the Institute of Surgical Research (ISR) through the ORISE Battlefield Airway Management Devices Research program. I aided with performing some of the mechanical tests as the writing of two articles.

Link to the first published article

The second article is accepted, not yet published.

November 2019 – December 2019

Seamax M-22 Float Plane Model

Skills/ Programs Used: Solidworks

Description: Solidworks group project (4 students). I was responsible for creating the main body piece, tail, windows, wheels, and combining all the parts in an assembly.

March 2018 – May 2018

Gesture Control Robot

Skills/ Programs Used: Arduino, AutoCAD Inventor, Circuits, Soldering

Description: My engineering group (3 people) created a robot that could be driven by sensors in a glove, and through certain hand movements. I helped with creating AutoCAD drawings, the circuit, the building of the chassis, and the testing.

August 2016 – Spring 2017

Centrifugal Water Pump

Skills/ Programs Used: AutoCAD Inventor, Laser Cutter Printer

Description: We designed and 3D-printed a centrifugal water pump in my senior year of high school. I was responsible for designing the casing of the pump.

August 2016 – Spring 2017

Robotic Car

Skills/ Programs Used: C+ Programming, AutoCAD Inventor, Laser Cutter Printer

Description: We (3 students) designed a robot that would fight other robots, inspired by the show battle bots. Requirements included it being remote-controlled, a limit of 4 motors, and must have 2 buttons that would turn off 2 corresponding motors. Unlike the other robots in the competition, I thought to delegate all our motors to wheels, rather than adding weapons (moving arm to hit opponents). This allowed us to have more power when pushing other cars. I cut parts of plexiglass designed on AutoCAD Inventor, to create a ramp and walls that would help to push opponents off the stage. We won 1st place against 7 robots because we were able to push the opponents off the stage, because we had the most power due to having all our motors used solely for our wheels.

August 2016 – Spring 2017

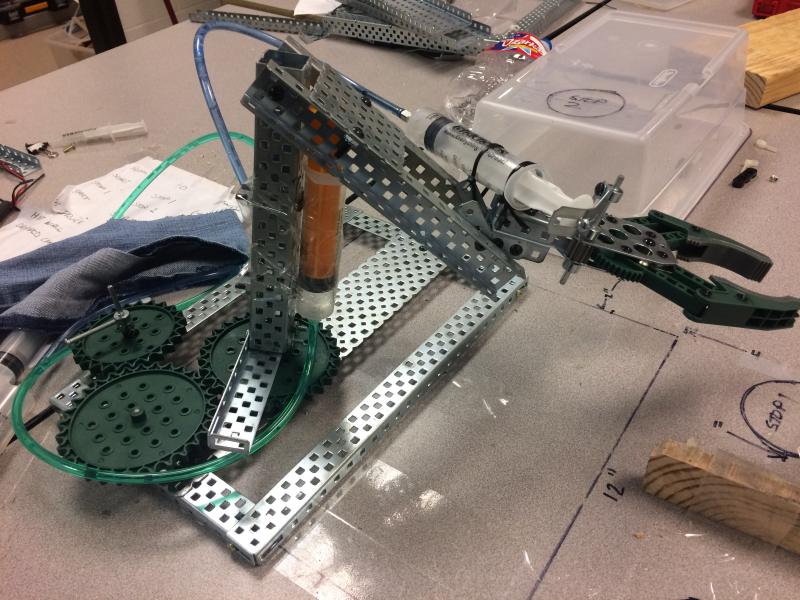

Hydraulic Arm

Skills/ Programs Used: Hydraulics

Description: We (3 students) designed a hydraulic arm capable of picking up an object and moving it to a higher location. This robot failed when one of the hydraulics gave out because maximum pressure was exceeded. If I were to do it differently, I would design it so that the arm wouldn’t be so heavy. It was split up into three main pieces and we made the mistake of making the middle section to be the heaviest, rather than the base of the arm.

August 2016 – Spring 2017

Laser Cut Truss Bridge

Skills/ Programs Used: AutoCAD Inventor, Laser Cutter Printer

Description: I designed this truss bridge capable of holding over 300 lbs. It was laser cut from plexiglass and was reinforced with additional designed plexiglass “spacer” pieces, metal pieces, and screws. My bridge held the most weight compared to 10 other bridges, the second closest held about 110 lbs.

August 2016 – Spring 2017

Makeup Brush Cleaner

Skills/ Programs Used: Circuits, Design

Description: We (2 girls) designed a spinning makeup brush cleaner. Once turned on, the brushes would spin in the machine that would be filled 3/4 of the way with soap and water. Used scraps of plexiglass from previous projects were used as a texture on the bottom to allow for a deeper clean within the bristles.